Get to know our line of products to wholesalers and retailers Discover our range of solutions for your sector.

SYVASA always committed to quality innovating to improve creative solving challenges

From start to finish we solve your metalworking production needs from the design and development of prototypes to finishing, packaging, quality control and shipping.

We have a specialized engineering department, which allows us to develop our parts, processes and devices in accordance with the best manufacturing practices worldwide. We have specialized software such as SOLIDWORKS, CADCAM, LANTEK, etc.

Our process can range from designing technical drawings for our internal manufacturing, as well as performing reverse engineering with a sample part and thus obtaining the elements necessary for manufacturing.

From the moment we are in contact with you you begin to live the SYVASA experience, we have an specialized area for the manufacturing of prototypes and thus give greater certainty to the production of your product. In addition to specialized machinery, personnel and procedures, we have a 3D Scanner and high-precision equipment to generate specialized reports such as PPAP, FAI, etc.

At SYVASA we are convinced that continuous improvement is the success of our production, using the best production practices, we have a production space of more than 3500m2, where we have the following processes:

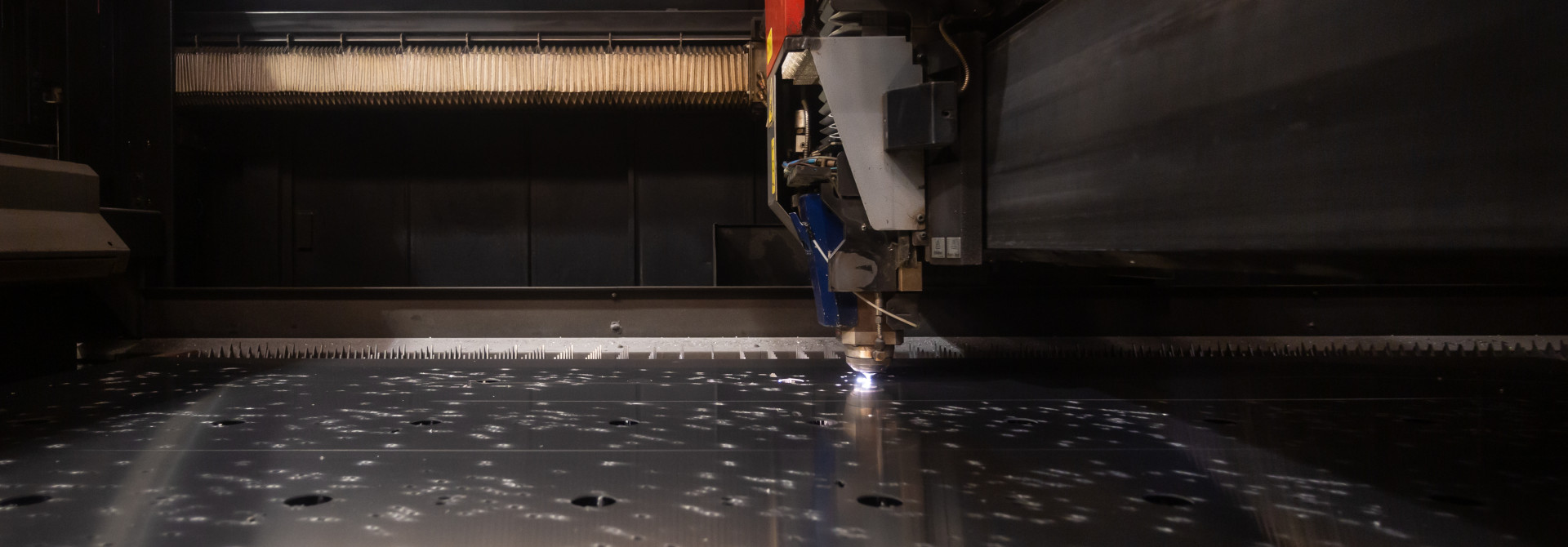

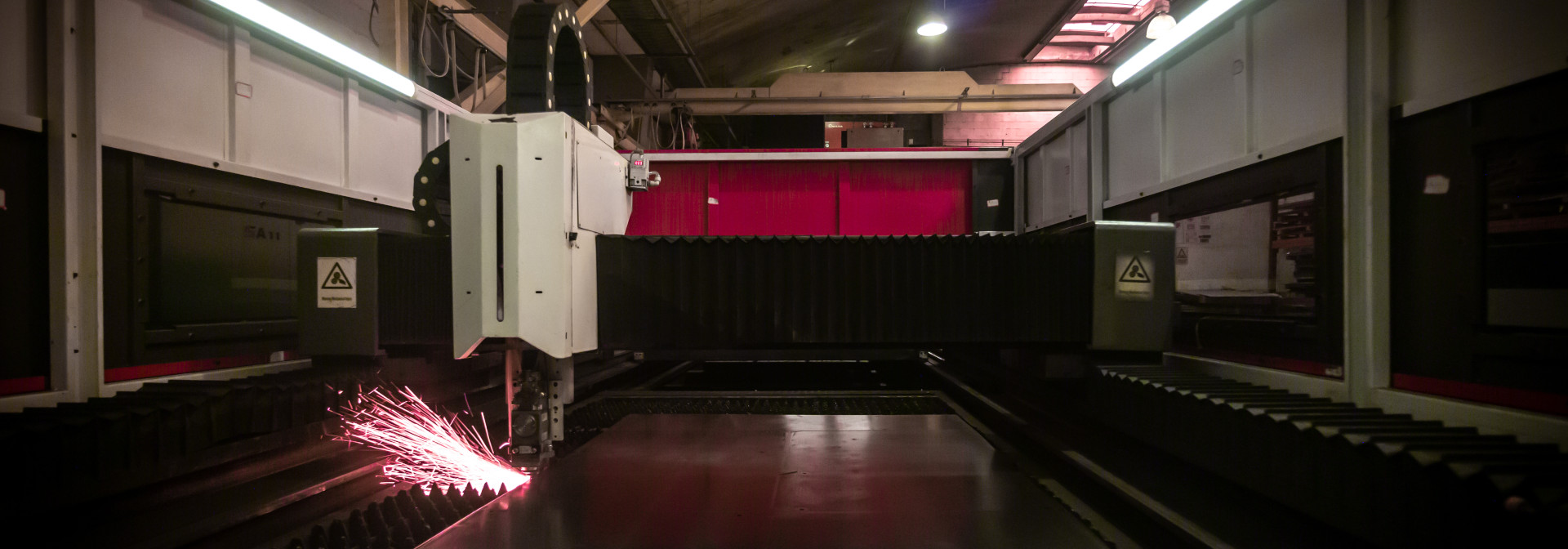

- 12 KW fiber optic laser cutting up to an inch and a half in carbon steel.

- Shear Cut: up to 5 meters in length and 5/8 in thickness

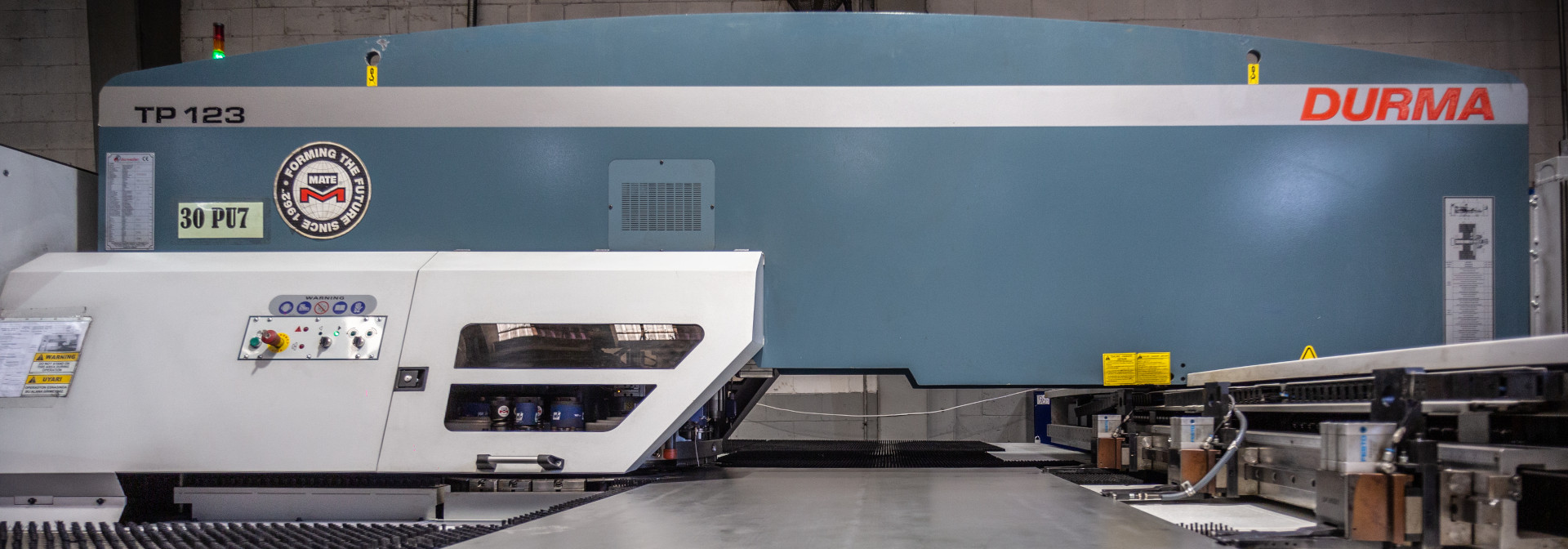

- Punching: 3 turret punching machines with up to 50 tons capacity

- Bending: 10 CNC bending machines up to 4 meters in length and 3/8 in thickness.

- Die-cutting: 6 die-cutting machines up to 250 tons capacity

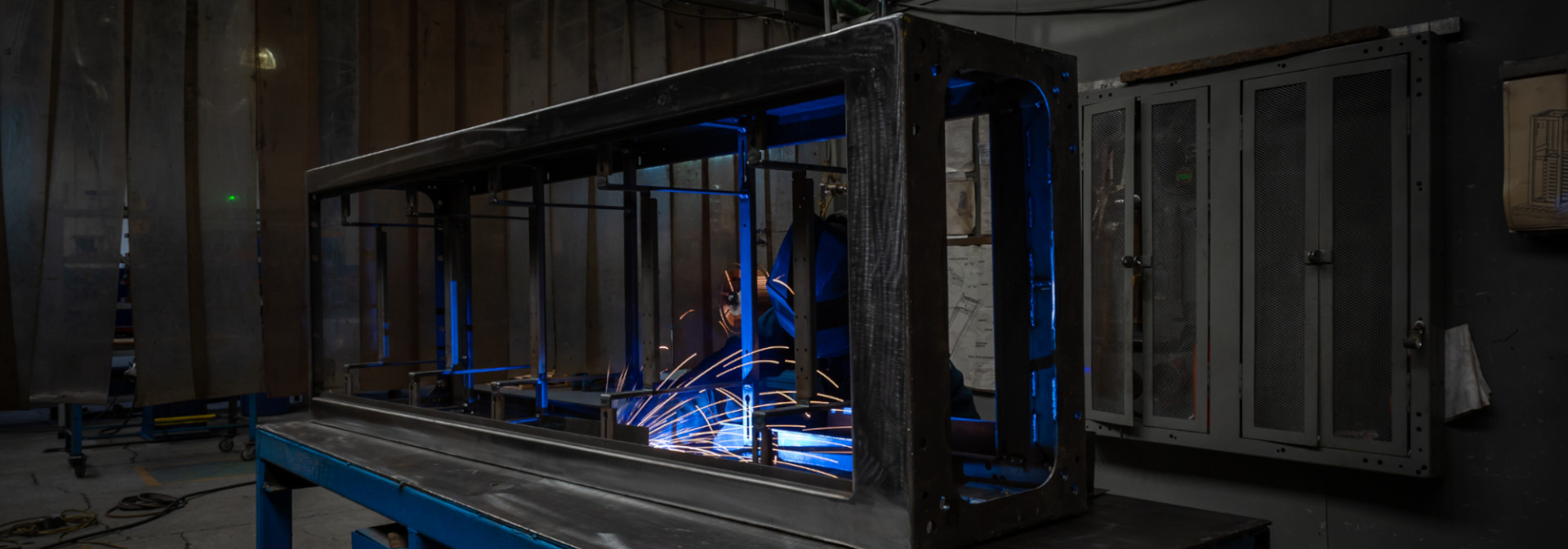

- Welding: More than 20 welding cabins (MIG, TIG, and 3 Spotwelding)

At SYVASA we are experts in the manufacture of metal parts and assemblies, but we also participate in projects that include the integration of other materials such as glass, wood and plastics, among others. Come to us, we will always seek to give you a solution